WORKPLAN

About workplan

Plan Realizacije

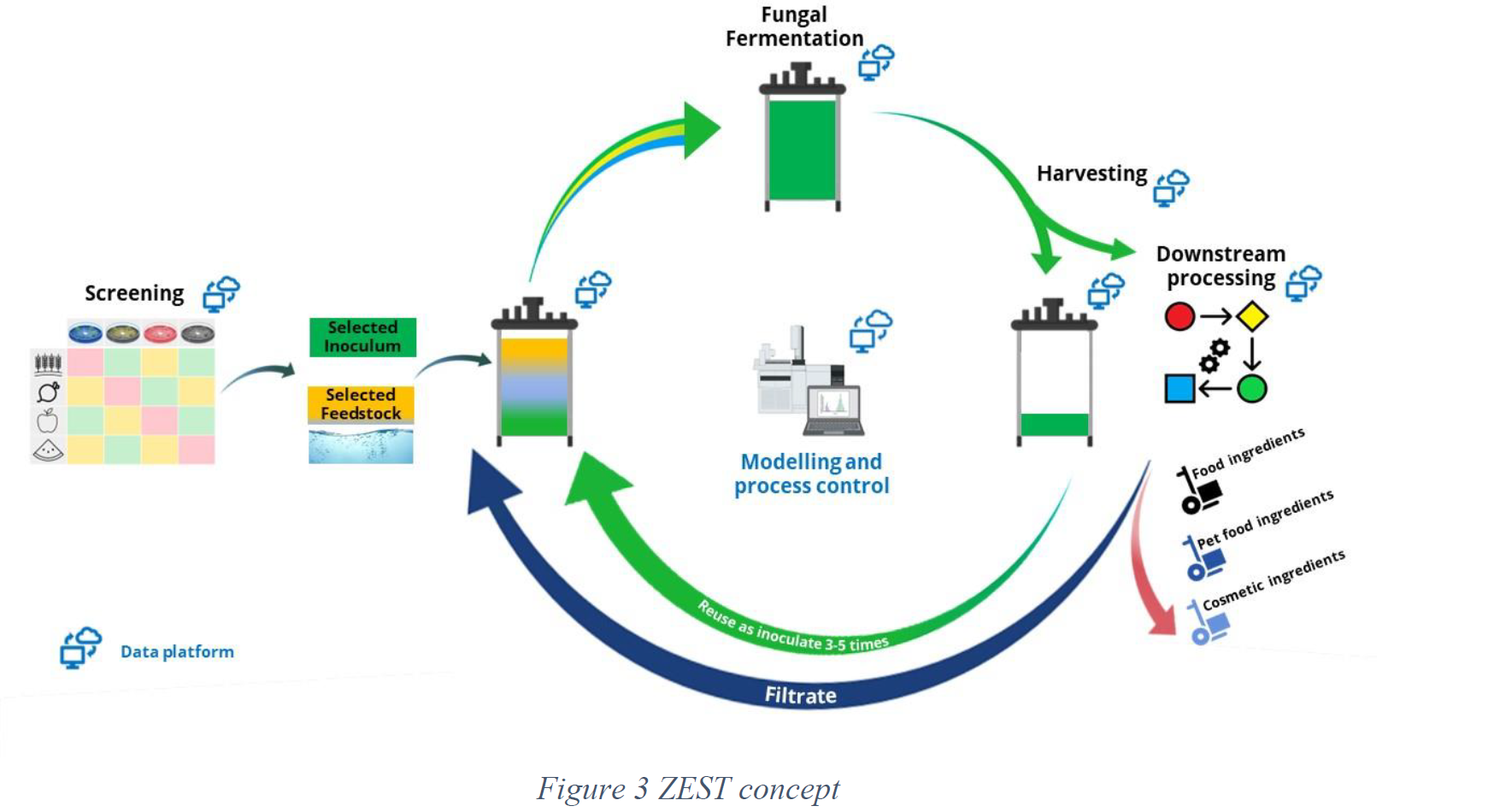

ZEST kicked-off in Juin 2023 and will cover a period of 48 months. It is structured in 9 interconnected work packages (WPs).

WP1 – Fungi Screening and Test Fermentation

WP2 – Bioreactor Design and Fermentation Upscaling

WP3 – Digital Modelling, Process Monitoring and Control

WP4 – Downstream Processes

WP5 – Product Development

WP6 – Safety and Sustainability Assessment

WP7 – Dissemination and Communication

WP8 – Business Modelling and Exploitation

WP9 – Project Management

WHY CHOOSE US

Iznad stanja tehnike

ZEST’s approach to mycelial fermentation in agricultural side streams will advance beyond the state of the art and offer solutions to current challenges.

These solutions outline the basis for the strategy set out in ZEST’s approach to an improved and modern fermentation production system resulting in a range of biological products. As a result, it will achieve a paradigm of minimal waste and full cascade usage along the entire production line.

Environmental and Ethical Challenges

Global livestock production has tripled in four decades and is expected to double by 2050, contributing 40% of global protein intake. It is linked to pollution, habitat loss, and ethical concerns.

Problems with traditional systems

Meat production contributes 15%-24% of global greenhouse gas emissions and faces criticism for its unsustainable and inhumane practices, raising concerns about its long-term viability.

Alternative protein sources

Various alternative proteins, such as insect, algae, and plant-based options, have been explored. However, challenges remain, including off-tastes, poor textures, costly processes, and scalability issues.

Potential of mycoprotein

Fungi-based mycoprotein offers a promising solution, with better texture and flavor compared to plant proteins. It also has greater scalability and environmental benefits, positioning it as a revolutionary alternative.

Don’t be shy!

If you are as passionate as we are about what we do, get in touch with us!