ABOUT

About

Concept and objectives

Project

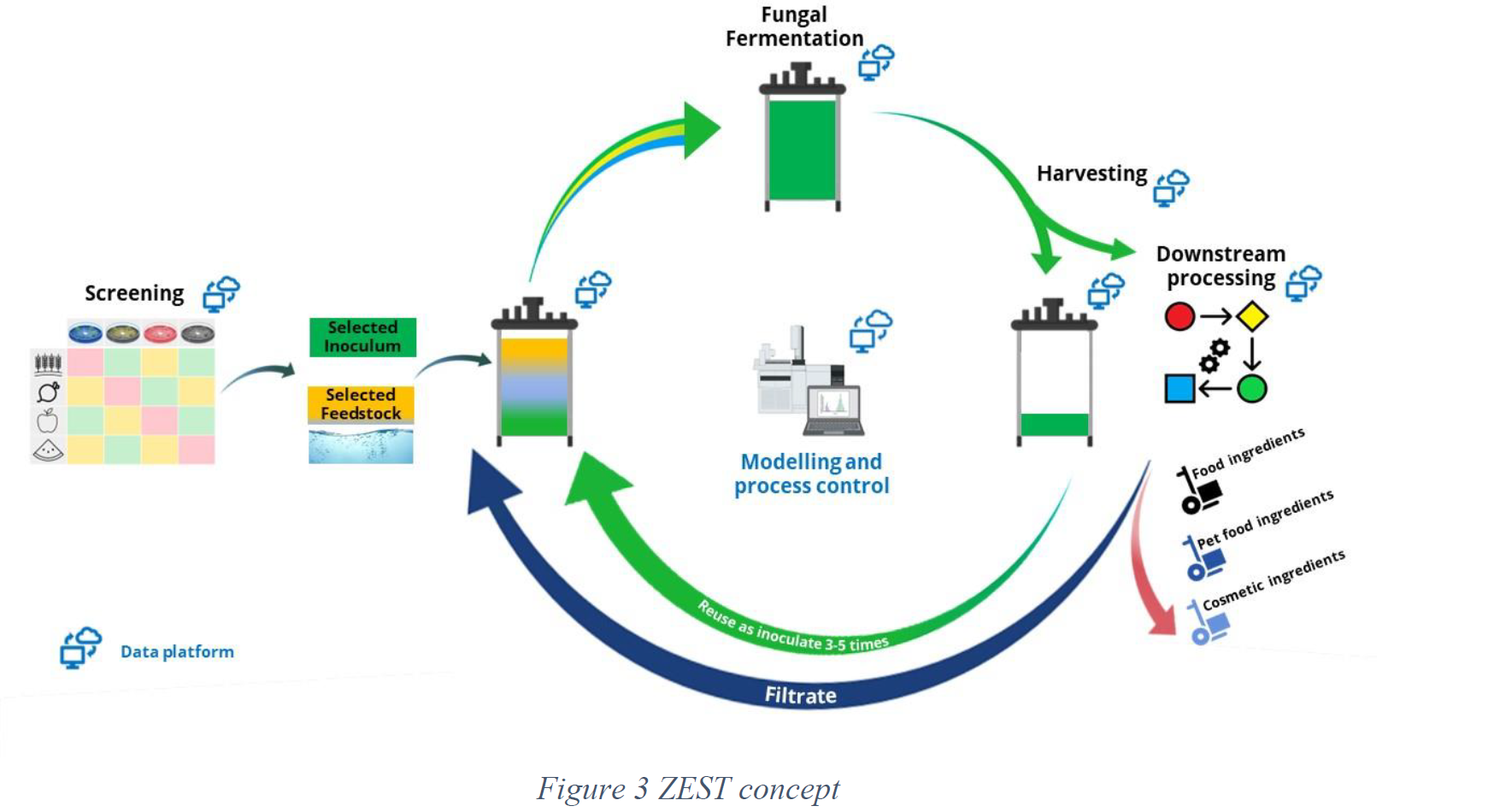

ZEST uses advanced technologies such as Artificial Intelligence (AI) to integrate process knowledge into control systems.

Primary objectives:

- Developing an efficient, zero-waste automatic production system.

- Designing a multipurpose bioreactor adaptable to substrates with varying viscosities and dry matter content.

- Assessing the entire value chains to ascertain their economic viability, market potential, environmental impact, and sustainability of fungal-based products.

The ZEST project, co-funded by the European Union and supported by the Circular Bio-based Europe Joint Undertaking (CBU JU) initiative, is driven by a collaborative consortium made up of twelve entities from five European countries.

About workplan

Workplan

ZEST kicked-off in Juin 2023 and will cover a period of 48 months. It is structured in 9 interconnected work packages (WPs).

WP1 – Fungi Screening and Test Fermentation

WP2 – Bioreactor Design and Fermentation Upscaling

WP3 – Digital Modelling, Process Monitoring and Control

WP4 – Downstream Processes

WP5 – Product Development

WP6 – Safety and Sustainability Assessment

WP7 – Dissemination and Communication

WP8 – Business Modelling and Exploitation

WP9 – Project Management

WHY CHOOSE US

Beyond the state of the art

ZEST’s approach to mycelial fermentation in agricultural side streams will advance beyond the state of the art and offer solutions to current challenges.

These solutions outline the basis for the strategy set out in ZEST’s approach to an improved and modern fermentation production system resulting in a range of biological products. As a result, it will achieve a paradigm of minimal waste and full cascade usage along the entire production line.

Experienced Professionals

Teritatis Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium dolore mque laudantium

Competitive Pricing

Teritatis Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium dolore mque laudantium

Eco-Friendly Practices

Teritatis Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium dolore mque laudantium

Positive Customer Reviews

Teritatis Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium dolore mque laudantium

The funding programme

Thanks to the support of the Circular Bio-based Europe Joint Undertaking (CBE JU), ZEST is a reality. The CBE JU is a €2 billion partnership between the European Union and the Bio-based Industries Consortium (BIC) that funds projects advancing competitive circular bio-based industries under Horizon Europe, the EU’s research and innovation programme.

Relevant initiatives

Some of the initiatives and sister projects that the ZEST project intends to team up with: